The factory floor of tomorrow is no longer the realm of science fiction. Today, a dynamic ecosystem hums with activity, where tireless machines seamlessly collaborate with intelligent systems – all orchestrated by the power of Artificial Intelligence (AI). This isn’t just about automation; it’s about an intelligent transformation that empowers human expertise and propels manufacturing toward a brighter future.

For decades, manufacturing has been the engine driving economic growth, delivering the physical goods that fuel societal progress. However, in today’s era of information overload, simply producing goods is no longer enough. Manufacturers find themselves drowning in a sea of data, struggling to unearth the valuable insights hidden within.

This is where AI steps in, assuming the role of a digital manufacturing maestro. AI boasts the remarkable ability to sift through mountains of data, swiftly identify complex patterns, and forecast emerging trends at an unprecedented pace. This makes AI not just an option, but an essential tool for manufacturers seeking a competitive edge in the global marketplace.

Power of Big Data

The sheer volume of data generated within the manufacturing sector surpasses most other industries. Every sensor, machine, and production line contributes a unique story to this vast data narrative. However, without the application of AI, this data remains nothing more than chaotic noise. Imagine an orchestra conductor taking the stage, transforming this cacophony of instruments into a harmonious symphony of actionable insights. This analogy perfectly captures the transformative potential of AI within the manufacturing landscape.

Predictive Maintenance

Imagine a future where machines can precisely forecast their maintenance needs. Predictive maintenance, fueled by AI, turns this vision into reality. By scrutinizing sensor data and historical patterns, AI can predict equipment failures before they occur. This translates to reduced downtime, fewer operational headaches, and substantial cost savings. Studies indicate that AI-driven predictive maintenance can slash unplanned downtime by up to 30%, marking a pivotal advancement for manufacturers.

One of the most significant applications of AI in manufacturing lies in predictive maintenance. Traditionally, maintenance schedules were reactive, leading to unexpected equipment failures, production downtime, and significant financial losses. AI, powered by predictive maintenance algorithms, flips the script entirely. By meticulously analyzing sensor data and historical equipment behavior, AI can predict equipment failures before they occur. This translates to reduced downtime, streamlined operations, and substantial cost savings. Studies reveal that AI-driven predictive maintenance can slash unplanned downtime by up to 30%, a monumental leap forward for manufacturers.

Quality Control on Steroids

Defects are the bane of any manufacturer’s existence, eroding profits and damaging customer satisfaction. AI, equipped with the power of deep learning, transforms into a hawk-eyed quality inspector, identifying defects with remarkable accuracy – reaching up to 90% in some cases. Imagine a system meticulously scrutinizing every weld, stitch, and component on the production line, ensuring only flawless products roll off the factory floor. This is the reality that AI-powered quality control brings to the table.

Optimizing Production

Production planning is an intricate dance, constantly juggling factors like material availability, production capacity, and ever-evolving customer demands. Fortunately, AI excels at these intricate maneuvers. By analyzing massive datasets encompassing historical production data, market trends, and supplier information, AI can recommend optimized production schedules. This empowers manufacturers to meet deadlines with unwavering precision, without sacrificing efficiency. The result? A significant boost in production throughput – studies have shown increases of up to 20% – and substantial gains in overall productivity.

Inventory Management

Imagine a system that keeps a watchful eye on your inventory, automatically adjusting stock levels to perfectly match demand fluctuations. No more scrambling for missing parts or tying up capital in unnecessary excess inventory. AI analyzes historical sales data, production schedules, and supplier lead times to predict future material requirements, guaranteeing the timely availability of the right materials, exactly when you need them. This translates to reduced procurement costs, minimized disruptions to production, and a leaner, more responsive operation.

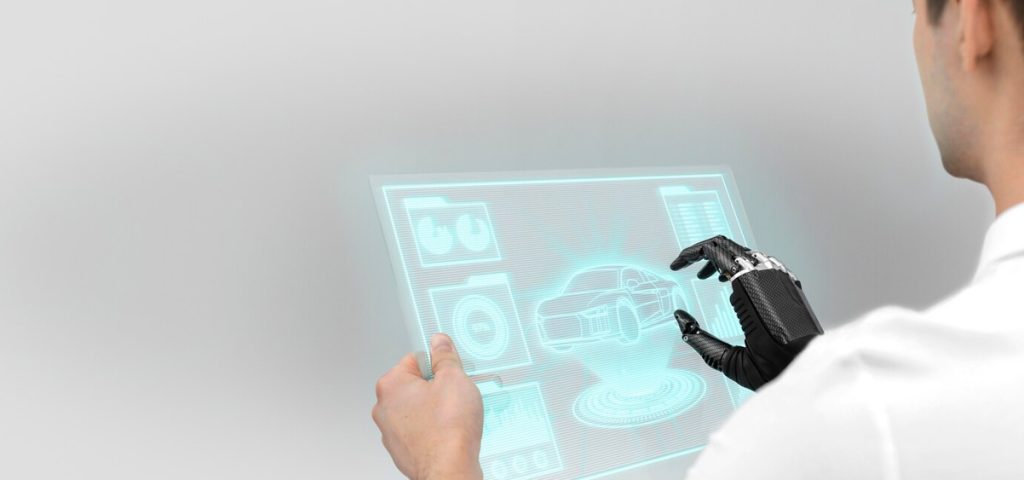

The Human Touch, Enhanced

It’s important to remember that AI is not here to replace human workers; rather, it’s here to augment them. AI empowers human employees by offloading tedious, repetitive tasks through automation and providing real-time insights to make informed decisions. Engineers can then focus their valuable intellect on innovation and problem-solving, leveraging AI-generated reports to anticipate orders, refine production strategies, and continuously improve efficiency.

QeDatalab: Your AI and ERP Partner

At QeDatalab, we are passionate about harnessing the transformative power of AI in manufacturing. Our team of seasoned consultants boasts over 25 years of experience in Enterprise Resource Planning (ERP) solutions. We specialize in seamlessly integrating AI into your existing systems, ensuring a smooth and efficient transition towards an intelligent future. Our goal is to empower manufacturers and distributors to leverage the combined power of AI and ERP to achieve operational excellence.

Don’t miss out on the AI revolution. Contact QeDatalab today and unlock the full potential of your manufacturing operation. Together, let’s create a future where AI and human ingenuity work in harmony, propelling your business to new heights.

Conclusion

The future of manufacturing is undeniably intelligent. As AI continues to evolve, we can expect even more groundbreaking applications, from intelligent robots collaborating with human workers to self-optimizing supply chains that adapt to real-time market fluctuations. By embracing AI now, manufacturers are not just keeping pace, they’re becoming the pioneers shaping the future of the industry. The key lies in recognizing that AI is not a replacement for human ingenuity, but rather a powerful tool to augment human capabilities. When human expertise and AI-powered intelligence work in harmony, the possibilities are truly endless. At QeDatalab, we’re here to guide you on this exciting journey. Let’s unlock the potential of AI together and forge a future where manufacturing thrives on the power of intelligent collaboration.