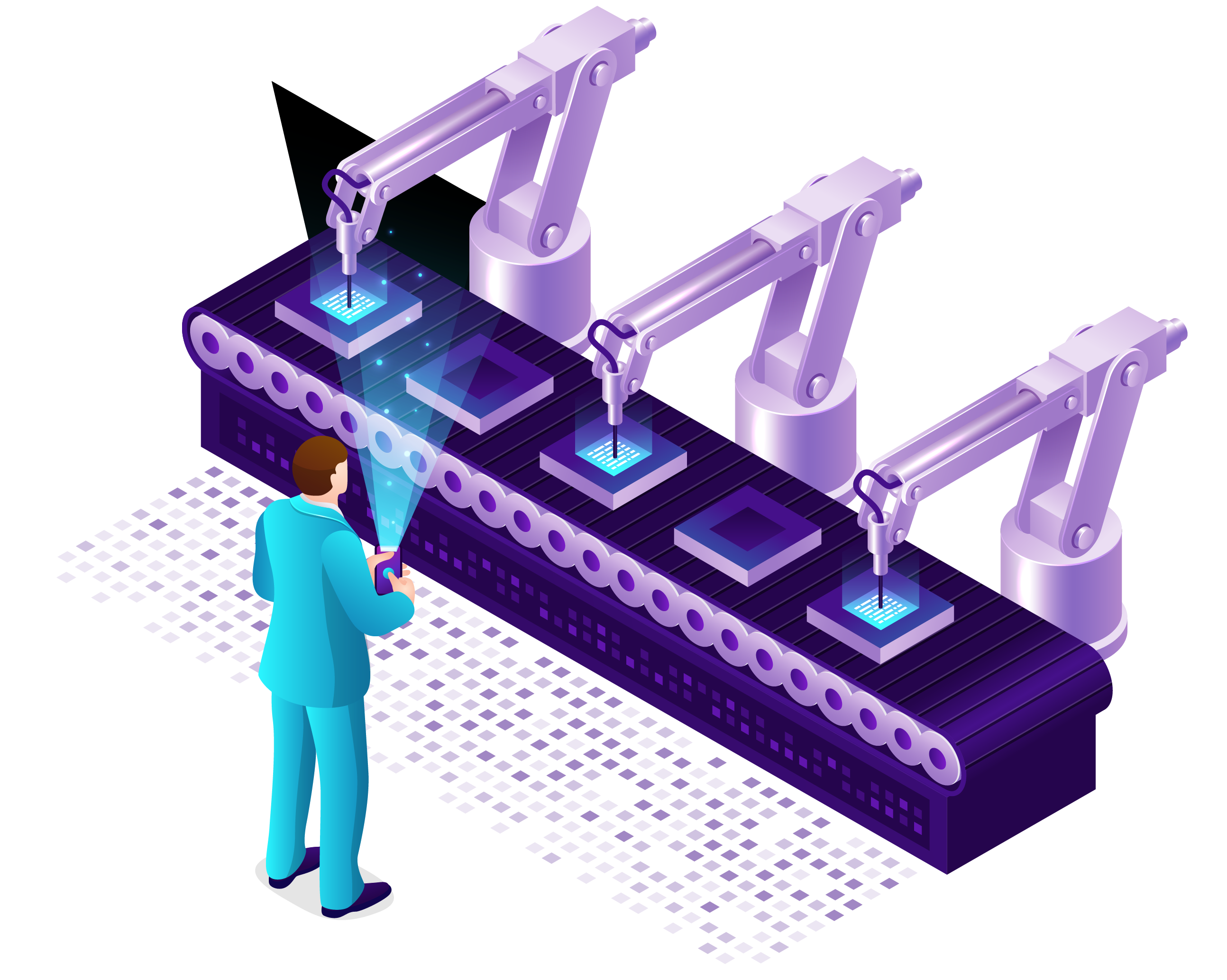

Facilitate Smart Manufacturing And Advanced Supply Chain With Our AI Solutions

Artificial intelligence enables data-driven innovative manufacturing business models and customer-centric services. Bridge the gap and simplify the complexity of manufacturing sectors with end-to-end AI solutions.

Leverage AI To Put The Right People, Process, And Technology In Place

Using AI in manufacturing means more automation, better efficiency, and new ideas for manufacturing products. By extracting valuable insights and patterns from the data it helps manufacturers to use resources better, make things faster, and produce more efficiently.

Amplify Efficiency

AI facilitates intelligent automation in manufacturing, reducing the need for manual intervention by streamlining production processes, minimizing human error, and achieving higher levels of efficiency.

Preventative Precision

AI algorithms can detect anomalies, and anticipate equipment failures and patterns indicative of potential malfunctions. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and reduces maintenance costs.

Quality Assurance

Inspect products with unmatched precision and identify the smallest imperfections to deliver products of superior quality. Computer vision helps minimize rework and reduce scrap rates by providing real-time defect detection.

Insightful Innovation

Uncover valuable patterns and trends from the data of production processes, supply chains, and customer feedback. Optimize production schedules, refine product designs, and anticipate market demands effectively to drive success and growth.

Integrate AI Today To Unleash The Future Trends

Be more agile, more collaborative, and more innovative with AI integration.